In manufacturing, selecting the right partners for injection mold china and aluminum die casting is highly significant. These techniques are essential in producing high-quality parts used in many different sectors. Today, we are going to discuss these methods of manufacturing and look at why it is advantageous to get them done in China which is known as a global center for precision engineering as well as cost-effective production.

The Chinese manufacturing sector has advantages that are unrivaled anywhere else; this is because they have good infrastructure, plenty of skilled laborers and abundant technological advancements among others. Involving chinese injection moulding skills plus aluminium die casting knowledge promotes straight through processing with short lead times while staying affordable at competitive rates for companies around the world. Additionally, no other country can beat china when it comes to meeting individual needs by altering products according to specific requirements thereby ensuring flexible efficient component fabrication procedures are followed always. The strength of supply chains coupled with logistical capabilities also makes china ideal for sourcing critical manufacturing services globally.

Injection Molding in China

The Process and Benefits

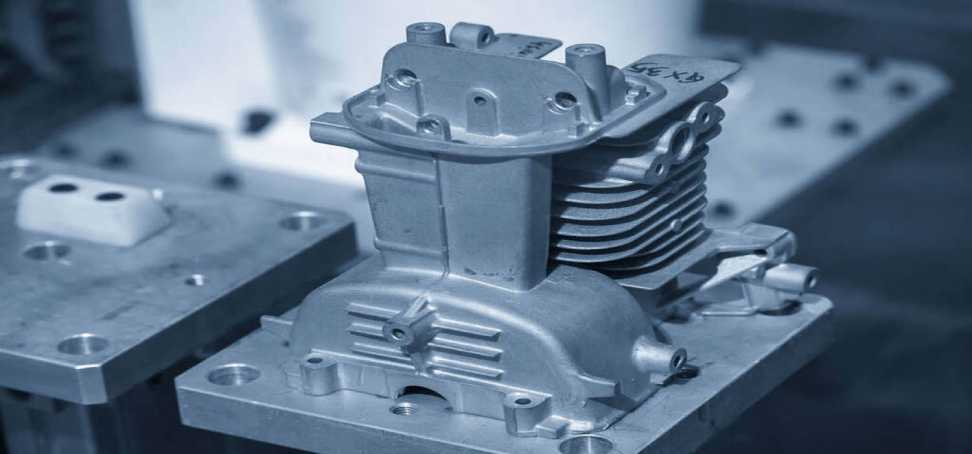

This is a highly efficient method whereby molten material is injected into a mold cavity until it solidifies into shape. The Chinese have perfected this art such that there are facilities which can handle intricate designs with large production runs. Here are some reasons why one should use injection molding in China:

- Cost-Effectiveness; Compared with many Western countries where labor rates remain relatively high, Chinese injection moulders offer competitive prices without compromising quality due to lower labour costs alone.

- Technological Expertise; State-of-the-art equipment and software programmes are used by Chinese manufacturers during their various stages of injection mould making process which therefore ensures accuracy each time they produce any given item.

- Versatility; Different sectors such as automotive parts or consumer goods require different materials along different design patterns but luckily all these needs can be met under one roof thanks to china’s diverse range of industrial capabilities especially when it comes down towards the plastic molding industry .

Choosing the Right Partner

To select an appropriate injection molder for your business needs consider:

- Experience and Reputation: Look out for companies that have been around long enough with positive customer feedbacks too.

- Quality Control Standards: ISO certification is universally acknowledged so check whether it’s adhered to by potential partners being considered as this shows commitment towards meeting international standards set within respective industries thus ensuring desired results.

- Communication And Transparency: Clear communication channels coupled with transparent pricing systems should characterize any good partnership between clients seeking services from third party providers like those involved in injection molding business within china.

Conclusion

To sum it up, the world has a lot to gain from using China’s injection molding and aluminum die casting manufacturing skills. Working with well-known Chinese producers is all companies need to do to know about modern techniques, save money when making things and have quality products that cannot be compared with any other. If businesses want reliable ways of producing goods in large quantities then they should look towards China because not only does this country come up with innovative ideas quickly but also knows how best to work on them thus creating efficiency throughout its system while still being able produce high end parts without compromising anything at all. The decision whether or not we partner up with manufacturers based here will determine our success and ability meet demand levels even though these facilities are located thousands miles away from where most people live!

Frequently Asked Questions (FAQs)

Q1: Why should a person choose China for injection molding and aluminum die casting?

Ans: China has good manufacturing facilities, a skilled workforce, and cost-effective production capabilities. The use of Chinese skills in the process of injection moldings and aluminum die castings helps industries to gain from new technology, competitive prices, and high quality manufacturing services.

Q2: What are some benefits of doing injection molding in China?

Ans: One advantage is that it can save costs because labor is cheaper than Western countries; another advantage is that they have better technology know-how which enables them have state-of-the-art equipment with more precision and versatility during their production processes.

Q3: How do I find an appropriate injection molding partner in China?

Ans: When selecting an injection mold making partner in China; look at their experience levels; check whether they are registered under relevant authorities; consider if they have been certified by ISO among others. In addition to this effective communication with them should be fostered so as to avoid any misunderstandings later on especially concerning pricing policies or delivery timelines.

Q4: What advantages does aluminum die casting offer in China?

Ans: In terms of material properties, aluminum die castings made by Chinese manufacturers possess superior qualities such as strength, durability, heat conductivity etcetera thus making them suitable for different industrial applications where complex shapes are required together with close tolerances being met consistently throughout production runs.

Have A Look :-

- Sonny Vaccaro Net Worth

- Is Auto Manufacturing a Good Career Path: Revving Up Your Future

- Is a Career in Professional Services Right for You? Unveiling the Path Less Traveled